No. 6,Mudanjiang Road,Liaocheng Development Zone,Shandong Province +86-188 65267322 [email protected]

GI Sheet Metal: The go-to choice for durability and safety

Introduction:

GI Sheet Metal is a type of metal that has been coated with a layer of zinc to protect it from rust and corrosion. The use of GI Sheet Metal has been on the rise in recent years due to its durability, safety, and ease of use. This article will highlight the various advantages of lurun gi sheet metal, including its notable safety features, recent innovations, its application in different industries, and how to use it for optimal results.

GI Sheet Metal has many advantages over other types of metals. One of the biggest advantages of GI Sheet Metal is its durability. The zinc coating on the metal protects it from rust and corrosion, which makes it last longer than other types of metals without the added cost of maintenance. Additionally, lurun gi galvanized sheet is fire-resistant, which makes it a popular choice in construction and electrical industries. Moreover, it is eco-friendly and recyclable, which makes it a responsible choice for companies that prioritize environmental sustainability.

Recent innovations in GI Sheet Metal have made it an even more versatile material. One of the innovations is the increase in the thickness of the zinc coating, which improves the durability of the metal. New techniques in coating have also enabled the production of GI Sheet Metal with different surface finishes such as glossy, matte, and textured. Such finishes are ideal in architectural and decorative applications, giving buildings an aesthetic appeal. Another commendable innovation is the development of weather-resistant lurun gi steel sheet that can withstand different weather conditions. This type of metal is ideal for outdoor structures such as roofing materials and fences, as it can withstand harsh weather conditions.

Safety features are important in any material, and GI Sheet Metal is no exception. One of the notable safety features of GI Sheet Metal is its non-toxicity, which makes it safe for use in food processing industries. Additionally, the metal is non-combustible, which means it will not catch fire or add to the intensity of a fire. Consequently, it is the go-to metal for fire-retardant constructions and electrical applications. With its superior resistance to corrosion and rust, lurun galvanized gi sheet is the perfect choice for outdoor applications where safety is a crucial consideration.

GI Sheet Metal has numerous applications in various industries. In construction, it is used for roofing, fencing, and siding applications, among others. The metal is also popular in electrical industries as it is a good conductor of electricity. The lurun precoated gi sheet is also widely used in the automotive industry, where it is used to construct vehicle body panels. The metal is also prevalent in the manufacturing industry, where it is used for storage racks, shelving, and cabinets. Its more recent application is in the solar panel industry as it provides a sturdy and weather-resistant backing to solar panels.

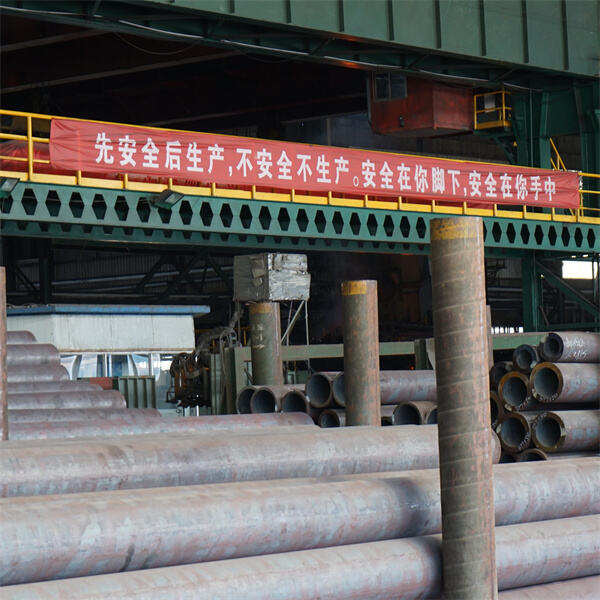

More than 30 years of experience. The company is an integrated modern steels enterprise group, which includes gi sheet metal spot storage international logistics, and products deep processing.

Innovations and product developments are vital to creating high-quality products that gi sheet metal.

World-class productions gi sheet metal that meets international certifications, and timely and professional after-sales services.

Integrity as a business principles, the best quality products, the gi sheet metal and a worldwide marketing networks.

To use GI Sheet Metal, one needs to take into consideration the thickness, strength, and gauge of the metal to ensure it is fit for the intended application. Cutting and bending the metal should be done with specialized equipment to prevent damage or warping. The metal should be fastened securely to avoid corrosion and rust. When painting lurun gi sheet, it is advised to use a primer before applying paint to prevent peeling or chipping of the topcoat. Proper handling is crucial to ensure optimal results and safety.