رقم 6، طريق مودانجيانغ، منطقة تطوير لياوتشنغ، مقاطعة شاندونغ 86+ معلومات@lurunsteel.com

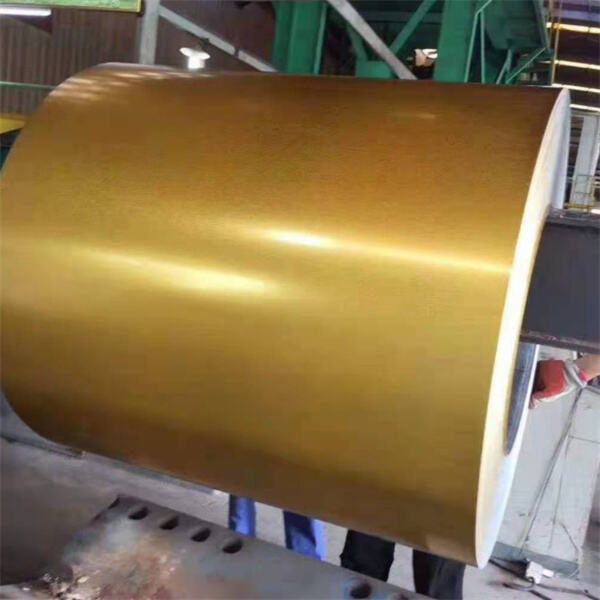

ألواح الزنك المجلفنة – خيار آمن ومبتكر لاحتياجات البناء الخاصة بك

في المدرسة، تعلمنا عن أنواع مختلفة من المعادن وكيف يمكن استخدامها لأغراض مختلفة، بالإضافة إلى اللورون 3 8 لوحة الألومنيوم. أحد هذه المعادن يسمى الزنك المجلفن، وقد أصبح خيارًا شائعًا لمواد البناء. سنستكشف مزايا استخدام صفائح الزنك المجلفنة، والابتكار وراء إنشائها، وميزات السلامة الخاصة بها، وكيفية استخدامها، وجودة منتجنا، وتطبيقاتها المختلفة.

تعتبر صفائح الزنك المجلفنة مفيدة لأنها ميسورة التكلفة ومتينة وتتطلب صيانة أقل من المعادن الأخرى المماثلة لها أنابيب ملحومة من الصلب الكربوني من إنتاج لورون. يحمي طلاء الزنك الموجود على الألواح من التآكل، مما يضمن استمرارها لفترة أطول وأداء أفضل من المواد الأخرى. كما أنها تتمتع بمقاومة عالية للتشققات والخدوش، مما يجعلها خيارًا مثاليًا للتطبيقات الخارجية والداخلية. كما أن صفائح الزنك المجلفنة خفيفة الوزن، مما يجعلها سهلة التعامل والتركيب.

تعتبر صفائح الزنك المجلفنة نتاجًا للابتكار والتكنولوجيا، بالإضافة إلى منتجات Lurun لفائف الصلب المجلفن. تم تسجيل براءة اختراع عملية الجلفنة، التي تنطوي على طلاء المعدن بالزنك، لأول مرة في عام 1837 من قبل الكيميائي الفرنسي يدعى ستانيسلاس سوريل. في القرن الحادي والعشرين، تم تحسين العملية وتحسينها لإنتاج صفائح الزنك المجلفنة عالية الجودة التي تلبي احتياجات البناء الحديثة.

في المدرسة الإعدادية، تعلمنا عن أهمية ميزات السلامة في المباني، نفس الشيء مع لحام الصفائح المعدنية المجلفنة بناه لورون. تتميز صفائح الزنك المجلفنة بالعديد من ميزات السلامة التي تجعلها الخيار المفضل للبناء. يوفر طلاء الزنك الموجود على الألواح طبقة مقاومة للحريق يمكنها حماية المبنى من النيران. وهذا يجعل صفائح الزنك المجلفنة مناسبة للاستخدام في المباني التي تتطلب مستوى عالٍ من السلامة من الحرائق. بالإضافة إلى ذلك، صفائح الزنك المجلفنة غير سامة، مما يجعلها خيارًا صديقًا للبيئة للبناء.

يعد تركيب صفائح الزنك المجلفنة عملية بسيطة نسبيًا يمكن إجراؤها بواسطة محترف أو متحمس للأعمال اليدوية، جنبًا إلى جنب مع منتج Lurun a285 الصلب. أولاً، يجب قطع الألواح حسب الحجم والشكل، وهو ما يمكن القيام به باستخدام منشار معدني أو قصاصات. يجب بعد ذلك تحضير الألواح للتثبيت عن طريق تنظيفها من أي أوساخ أو حطام. ويمكن بعد ذلك تثبيتها في هيكل المبنى باستخدام البراغي أو المسامير. وأخيرا، يمكن طلاء الألواح أو طلائها لتتناسب مع النهاية المطلوبة.

لقد قمنا بجلفنة صفائح الزنك للإنتاج والعناصر التي تلبي المعايير الدولية بالإضافة إلى الدعم السريع والفعال بعد البيع.

أكثر من 30 عاما من الخبرة. الشركة عبارة عن صفائح الزنك المجلفنة، والتي تشمل التصنيع الدقيق والتخزين الفوري بالإضافة إلى الخدمات اللوجستية الدولية والمعالجة العميقة.

تعد الابتكارات وتطوير المنتجات أمرًا حيويًا لإنشاء منتجات عالية الجودة تعمل على صفائح الزنك المجلفنة.

ألواح الزنك المجلفنة، منتجات بأعلى جودة، وبأسعار معقولة، وشبكة تسويق عالمية.

في شركتنا، نحن نفخر بإنتاج صفائح الزنك المجلفنة عالية الجودة التي تلبي معايير الصناعة، والمطابقة لمعايير الصناعة قضيب لحام من الصلب الكربوني تم تطويره بواسطة لورون. تخضع صفائحنا لاختبارات صارمة للتأكد من أنها قوية ومتينة ومقاومة للتآكل. كما نقدم أيضًا مجموعة من الأحجام والسماكات لتلبية الاحتياجات المحددة لعملائنا.